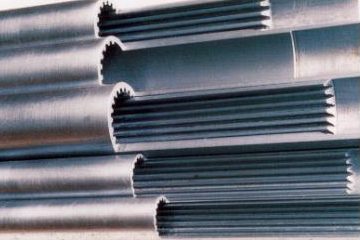

Low finned tube

Steel pipes used in power plants, oil refineries, cooling equipment, and a variety of other heat exchange devices.

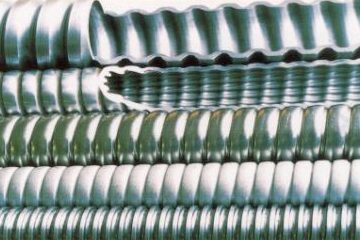

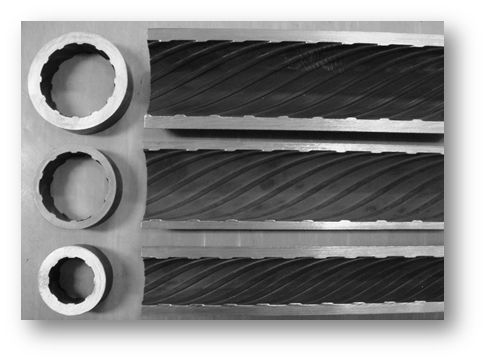

Low finned tubes involve rotational processing of the outer surface of steel tubes to create a fin shape. A steel pipe length of 25.4 mm (1 inch) per fin and 19 fins is a design often used.

We can also produce units with 26 fins. The pipe’s outer surface area becomes 3.5 times that of the inner surface area and possesses superior heat transferability compared to normal, round pipes. By improving the heat transferability of a pipe, it can minimize (capacity, weight reduction) into a variety of devices, reduce material cost, reduce shipping cost, and improve the amount of space taken up.

The uses differ, but as far as pipes with an increased outer surface area are concerned, they are all tubes with welded peripheral fins onto steel pipes, also known as high fin tubes. Low finned tubes involve the formation of fins by direct rotational processing of steel pipes, meaning there is no worry of detachment even if later bent. Moreover, they possess excellent durability and anti-vibration properties once put into operation.

We produce 2 versions of fins per inch. On a steel pipe length of 25.4 mm (1 inch) you can choose 19 fins or 26 fins. 19 fins per inch is the design often used.

Even high finned tubes are available through a partnership with cooperating companies, so please feel free to inquire. With high finned tubes, fins can be made from aluminum or stainless steel. By combining cold drawn steel tubes and high fin processing, we can respond to customer’s material, delivery deadline, and quantity needs as far as possible.

APPLICATIONS OF LOW FINNED TUBES

Low-finned tubes are used in following fields:

+ heat exchangers for power plants (nuclear, electric, thermal and geothermal power plants)

+ chemical and petrochemical industries

+ high corrosive systems (evaporators, condensers,...)

+ food processing and refrigeration industries.

Standard dimensions for 19-fin unit (19 fins per inch)

26-fin units are also available. Please feel free to contact us about 26-fin unit dimensions.

Potential range of manufacturing

In some cases, it may be possible to work outside the potential range of manufacturing. Please feel free to contact us.

Material

We fabricate with carbon steel and steel alloys as well.

Dimensions

We can provide the outer diameter of 15.88 mm, 19.05 mm, or 25.40 mm. We make products with 19 fins per inch (25.4 mm).

Others

Rotational processing gives the pipe a larger outer surface area than the original pipe. Please feel free to contact us about dimension details.

Other Specifications

- After processing fin, we carry out excess current deep damage testing. Moreover, all units can undergo SR per customer request.

- The minimum length for the middle land is 25±5 mm and unprocessed dual end minimum length is 25±5 mm.

- Incomplete start/end fin processing length is, in total, less than 120 mm.

- Maximum length for fin processing is 19.5m or less, and total length tolerance is +10 mm/-0 or ±5 mm.

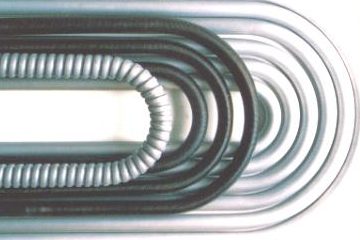

- We can also make post-fin processing U turn bending. In this case, we can fabricate the R portion with or without fins.