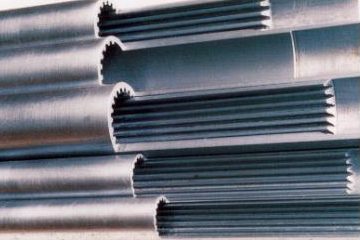

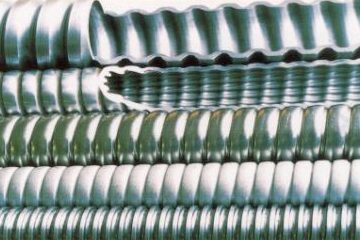

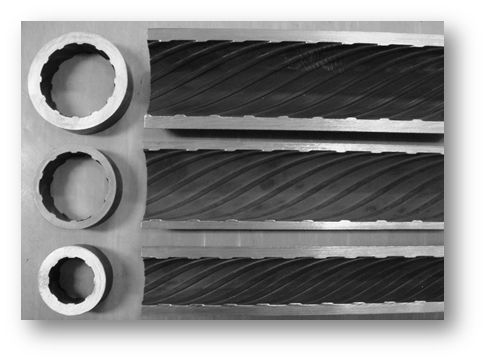

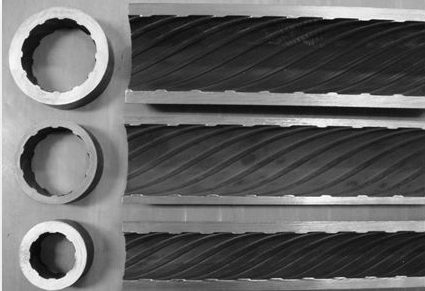

Rifled Tube (Internally ribbed tube)

Steel pipes used in furnace power plants and other facilities with high temperature and pressure that are used to prevent film boiling.

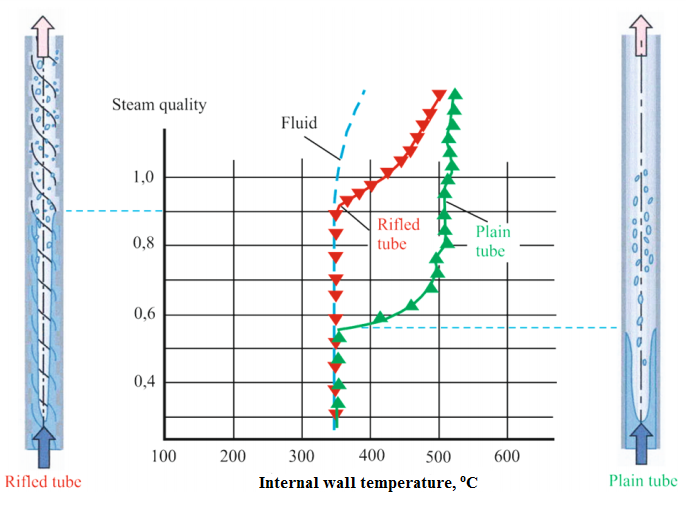

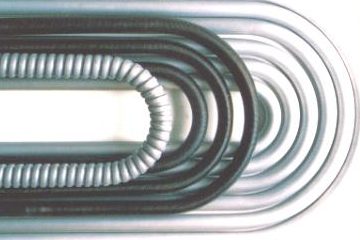

Inside the water wall pipes of boilers in sub-critical steam power plants, water boils into steam vapor. Inside high temperature/high pressure boiler devices, a special type of boiling called film boiling occurs. The boundary between the fluid and water wall pipe forms a layer of steam. When film boiling occurs, the heat transfer efficiency is reduced due to the steam layer. Since heat cannot be effectively transferred from the pipe to the water, the pipe temperature rise can cause boiling explosions due to overheating, resulting in facility damage. A rifled tube contains multiple butterfly ribs on the inner surface of the steel pipe, whisking the water inside and causing turbulence that suppresses film boiling. Multiple ribs greatly increase the internal surface area of the pipe compared to rib-less steel pipes, resulting in increased boiler energy output efficiency. Internally ribbed tubing helps to decrease mass flow and ensures sufficient cooling for the internal surfaces of tubes.

Furnace power plant boilers in recent years have demanded improved fuel efficiency and improved (reduced) CO2 exhaust. These improvements require steam vapor to heat up and reach a high pressure, which is why rifle tubes are needed.

With first-ranked Japanese mother tube along with the experienced process of production as well as strict inspection, we are proud to be the number one manufacturer of tubes for heat exchanger in Japan.

Source: Karol Majewski, Journal of Power Technologies 93 (2013)

With first-ranked Japanese mother tube along with the experienced process of production as well as strict inspection, we are proud to be the number one manufacturer of tubes for heat exchanger in Japan.

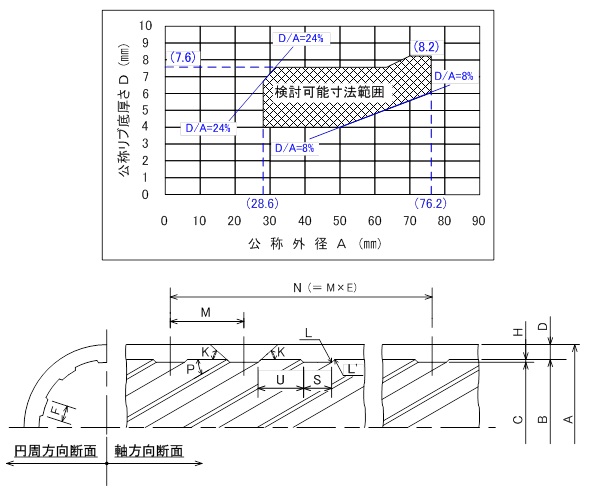

Potential range of manufacturing

In some cases, it may be possible to work outside the potential range of manufacturing. Please feel free to contact us.

Material

We manufacture with low carbon steel tube and low alloy tube.

Dimensions

We can provide the outer diameter range from 28.6 mm to 76.2 mm.

Others

Rib lead angle: 30 degrees relative to pipe axis

Potential range of manufacturing and dimensional specification cross section graph